International group of physicists including specialists from Landau Institute for Theoretical Physics improved their model describing damage processes in ruthenium thin films induced by powerful femtosecond laser. Such films are used as coatings for the mirrors of the European X-Ray Free-Electron Laser Facility (XFEL). This is a unique device that helps scientists to map atomic details of viruses, make snapshots of chemical reactions and even make “videos” of them. Understanding what happens when powerful laser pulse interacts with thin films, scientists can create more long-lasting covers for XFEL mirrors. Article is published in Applied Surface Science journal.

European X-Ray Free-Electron Laser Facility (XFEL) is a unique research device generating very powerful laser impulses in broad frequency spectrum but mainly in X-ray. The brilliance of these ultrashort flashes produced 27 000 times per second is a billion times higher than that of the best conventional X-ray radiation sources. With the help of world's largest X-ray laser, researchers are able to map the atomic details of viruses, decipher the molecular composition of cells, take three-dimensional images of the molecules and even make “videos” of chemical reactions, including those occurring in catalytic processes that are of fundamental importance for the chemical industry.

Because of high energy of the X-ray photons, conventional optics cannot be used in the appliance. X-rays are absorbed by all substrates, and to operate XFEL they must be reflected. To solve this problem and make the beams reflect in necessary direction scientists employ special mirrors coated with thin films of heavy metals, such as gold or ruthenium (gold is more widespread, but ruthenium is significantly cheaper). Mirrors are placed so that X-rays interact with their surfaces at gliding (very small) angles and are partially reflected.

But ultrapowerful X-ray laser impulses inevitably damage mirror’s coating. Understanding what happens when powerful laser pulse interacts with thin films, scientists can create more long-lasting covers for XFEL mirrors. “However, in order to do this we must have a model that thoroughly describes what happens when X-ray impulses collide with film coating”, say co-authors of the new article, leading researcher of ITP Plasma and Lasers department Nail Inogamov and researcher of University of Twente in Netherlands Igor Milov. “We’ve been creating such model since 1970s and today it describes processes occurring during laser ablation in solids with different lasers with minute details. Using our model, we can accurately predict the consequences of thin film irradiation in different conditions”.

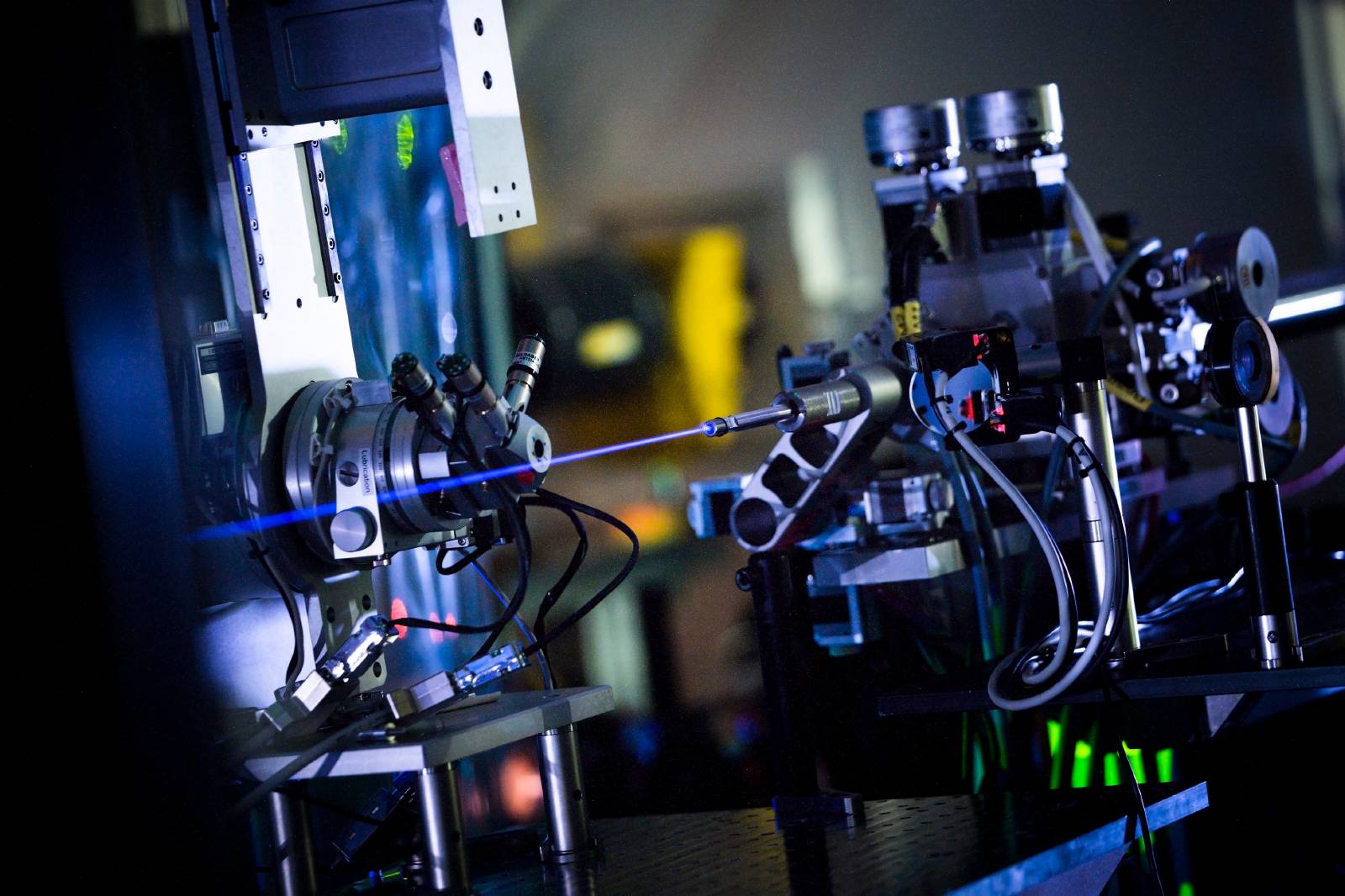

X-ray beam generated at XFEL device. Photo European XFEL / Jan Hosan

When powerful coherent X-ray beam interacts with film or any other metal target, material starts to evaporate from target surface due to extreme heating. This is called laser ablation. When laser fluence surpasses given threshold value, material explodes, generating explosive crater. Such ablation craters damage the reflective capacity of the mirrors. However, direct studying of metal films ablation caused by high fluency laser is impossible, because these processes happen too fast to be registered by existing devices. On the first stage metal electrons absorb laser energy and “heat up”. Next they transfer obtained extra energy to the ions of the metal grid. “All these processes are very unique for their unusual physics, thermodynamics and thermal conduction”, explains Inogamov. “Our model enables us to calculate a lot of different parameters. For example, we can determine how long electrons will stay in excited state or how fast they will transfer energy to the grid. It’s very important to know all these details to predict how bad the damage will be”.

Scientists performed their XFEL damage experiments using 50 nm thick ruthenium films and femtosecond pulses with 92 eV photon energy (extreme ultraviolet) and 1,2 eV (optical range). They also used data obtained in previous experiments on XFEL facility, when ruthenium films were exposed to single-shot femtosecond pulses with 7 and 12 keV photon energy (hard X-rays). Dimensions and other characteristics of generated ablation craters were analyzed by means of scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Experimental results were then compared to the theory predictions. “Predictions of our model were in very good consistence with XFEL data. We were able to calculate the threshold energy of film damage with the accuracy of 5-10%. Other existing models enable you to assess this parameter only within an order of magnitude. Such good fidelity is a proof that our model adequately describes real ablation processes”.

As an additional result of their experiments scientists have discovered a number of general patterns specific to the ruthenium films ablation induced by laser with different characteristics. This new research not only deepens our understanding of ablation processes. Obtained results will be useful in creating a sort of “ablation libraries” – models describing ablation processes for the different metals and laser parameters. Such libraries will help to radically decrease the number of extremely laborious and expensive experiments aimed to analyze individual metals as possible candidates for the XFEL mirror coatings or any other appliances that involve laser ablation.

To arrange an interview, ask for the comments or additional information, please contact [email protected].